Light duty racking systems are essential for many warehouses and storage facilities, providing a versatile and efficient solution for organizing and storing lighter items. However, to ensure their longevity and safety, regular maintenance is crucial. This article offers practical advice on maintaining light duty racking systems, including regular inspections and cleaning routines.

Regular Inspections

1. Visual Inspections: Conducting regular visual inspections is the first step in maintaining your light duty racking system. Look for any signs of damage, such as dents, bends, cracks, or corrosion. Address these issues promptly to prevent potential accidents or further damage. Inspections should be performed at least once a month, but more frequent checks are advisable in high-traffic areas.

2. Structural Integrity: Check the structural integrity of the racks. Ensure that all components, such as beams and uprights, are securely fastened and free from damage. Pay special attention to the connections between different parts of the racking system. Loose bolts or connectors can compromise the stability of the entire structure.

3. Load Distribution: Ensure that the weight on the racks is evenly distributed. Overloading one section can lead to structural failure and accidents. Follow the manufacturer's guidelines regarding load limits and avoid placing heavy items on the upper shelves. Instead, store heavier items on the lower shelves to maintain a lower center of gravity and enhance stability.

Cleaning Routines

1. Regular Cleaning: Keeping your racking system clean is essential for its longevity and safety. Dust and debris can accumulate on the racks, leading to corrosion and other damage. Regularly wipe down the racks with a damp cloth to remove dust and dirt. Avoid using water directly on the racks, as it can cause rusting.

2. Floor Cleaning: The floor around the racking system should also be kept clean. Dust and debris on the floor can be kicked up onto the racks, leading to dirt accumulation. Sweep and mop the floor regularly to maintain a clean environment.

3. Sanitation: Sanitizing the racking system is particularly important in environments where food or sensitive items are stored. Use appropriate sanitizing agents to eliminate bacteria and other contaminants. Depending on the activity level in the warehouse, sanitation might be done daily, weekly, or monthly.

Maintenance of Components

1. Beams and Uprights: Regularly check the beams and uprights for any signs of wear and tear. Beams can bend or warp due to overloading or accidents, and uprights can suffer from corrosion or bending. Replace any damaged components immediately to maintain the structural integrity of the racking system.

2. Floor Anchors: Ensure that the floor anchors are securely fastened. Loose or broken anchors can compromise the stability of the racks. Regularly inspect the anchors and tighten or replace them as necessary.

3. Protective Equipment: Invest in protective equipment such as column protectors and rack guards. These can help prevent damage from forklifts or other heavy equipment. Regularly inspect the protective equipment for any signs of damage and replace them if necessary.

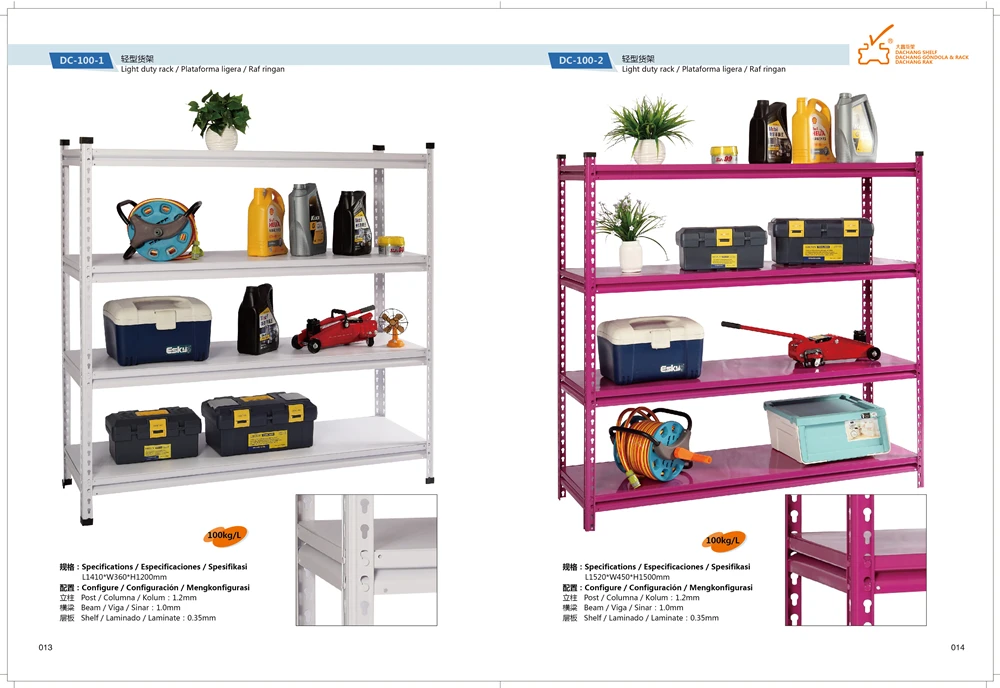

Dachang Light Duty Racking

● Dachang Racking & Shelving Light storage racks are composed of three parts: uprights, beams, and laminates.

● The light-duty shelf has a beautiful appearance and easy assembly, and the steel laminate can be adjusted up and down with a spacing of 55mm.

● Multiple sets of lightweight shelves can be connected to increase the overall stability of the shelves.

● The laminates are welded with reinforcing ribs, and the load capacity of each layer is large, and the maximum load capacity of each layer can reach 100kg or 150kg/layer under the relative length.

● The top and bottom decks and the uprights are connected by angle codes and bolts, which are safe and stable, and the middle decks are connected with the decks with special pins, which are simple and convenient and can be adjusted arbitrarily.

● The surface treatment adopts shot blasting to remove rust and oil, and electrostatic powder spraying treatment, which can be sprayed according to the color specified by the customer.

It has the advantages of beautiful color, not easy to oxidize, easy to clean, and so on. It is widely used in enterprise warehouses, supermarkets, and institutions, and Dachang Racking & Shelving has reached the same level of products in developed countries. Anti-static facilities can also be added to the laminate to make anti-static shelves, which are now widely used in electronic enterprises. The light shelves in the same direction can also be bolted to form the whole shelf.

| Product Type | Light Duty Racking |

| Product Name | Warehouse Storage Racks, Light Duty Storage Racking |

| Model No. | C100-1 |

| Usage | Warehouse, Enterprise Warehouse, Grocery Store, Market, Convenience Store, Supermarket, Garage etc... |

| Product Size | Length: 1410mm Width: 360mm Height: 1200mm; 1500mm; Customized Available |

| Loading Capability | 100-150KGS/Layer, Depend on detail customer required, by negotiated |

| Process | Cut-Forming-Bend-Shape-Polish-Power Coating-Packing etc.. |

| Surface Finished | Powder Coating/Painting/Chrome/Finishing Polish etc.. |

| Color | Customized |

| Design | Custom Free Design,Professional Design Team |

| OEM/ODM | Available |

| Packing | Uprights are packed in bubbled plastic film,others are packed in seaworthy cartons. |

| Payment | 30% deposit and 70% on or before delivery by T/T. |

Conclusion

Maintaining a light duty racking system requires regular inspections, cleaning routines, and adherence to proper loading procedures. By following these maintenance tips, you can ensure the longevity and safety of your racking system, prevent accidents, and protect your goods.

To learn more about how Dachang's light duty racking system and expertise can benefit your industry, please visit our website or contact us today. We look forward to working with you to realize the full potential of light duty racking system for your business.

.jpg)